CONTACT US

- +90 332 251 18 04

- +90 332 251 18 04

- bilgi@yilmazogullaridegirmen.com.tr

- Büyük Kayacık Mah. 3. Organize Sanayi Bölgesi 7 Nolu Sokak No:25 Selçuklu / Konya / Türkiye

We Manufacture the Mill Technologies

of the Future Today.

Reliable machines, powerful performance.

50+

Countries Exported To

Excellence-Oriented Production

Yılmazoğulları Mill stands out in the milling machinery industry with high-precision manufacturing technologies. From quality control processes to assembly lines, every stage is managed in accordance with international standards.

We produce for a sustainable future.

With a focus on energy efficiency, long-lasting components, and an environmentally friendly production philosophy, we shape not only today’s but also tomorrow’s milling technologies. Our goal is to ensure that every investment delivers value for many years.

24/7 Non-Stop Operation

We manage the entire process from discovery and project design to manufacturing, assembly, and commissioning, all from a single source.

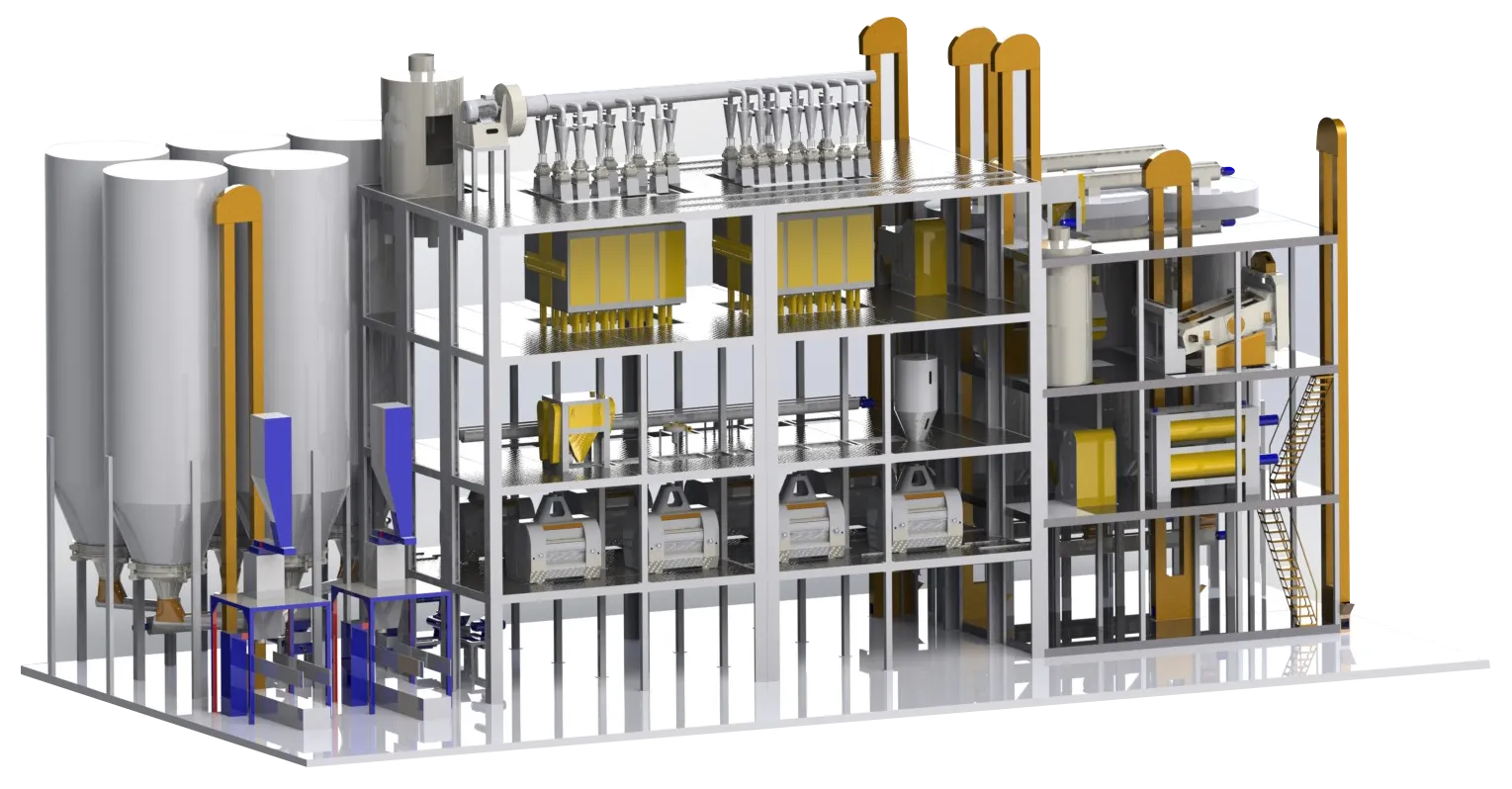

Turnkey Flour Project Evaluations

We manage the entire process from discovery and project design to manufacturing, assembly, and commissioning, all from a single source.

We Have Brought the Milling Machines of the

Future to Today!

Grinding Unit

Yılmazoğulları Grinding Units are designed to provide homogeneous, controlled, and high-capacity grinding performance for various raw materials. Their durable construction and energy efficiency ensure maximum productivity in industrial production lines.

Precise and Homogeneous Grinding

Thanks to its advanced mechanical design, it maintains product quality and ensures consistent grain distribution.

Durable Industrial Structure

Its body, suitable for heavy-duty use, ensures long-lasting and reliable operation.

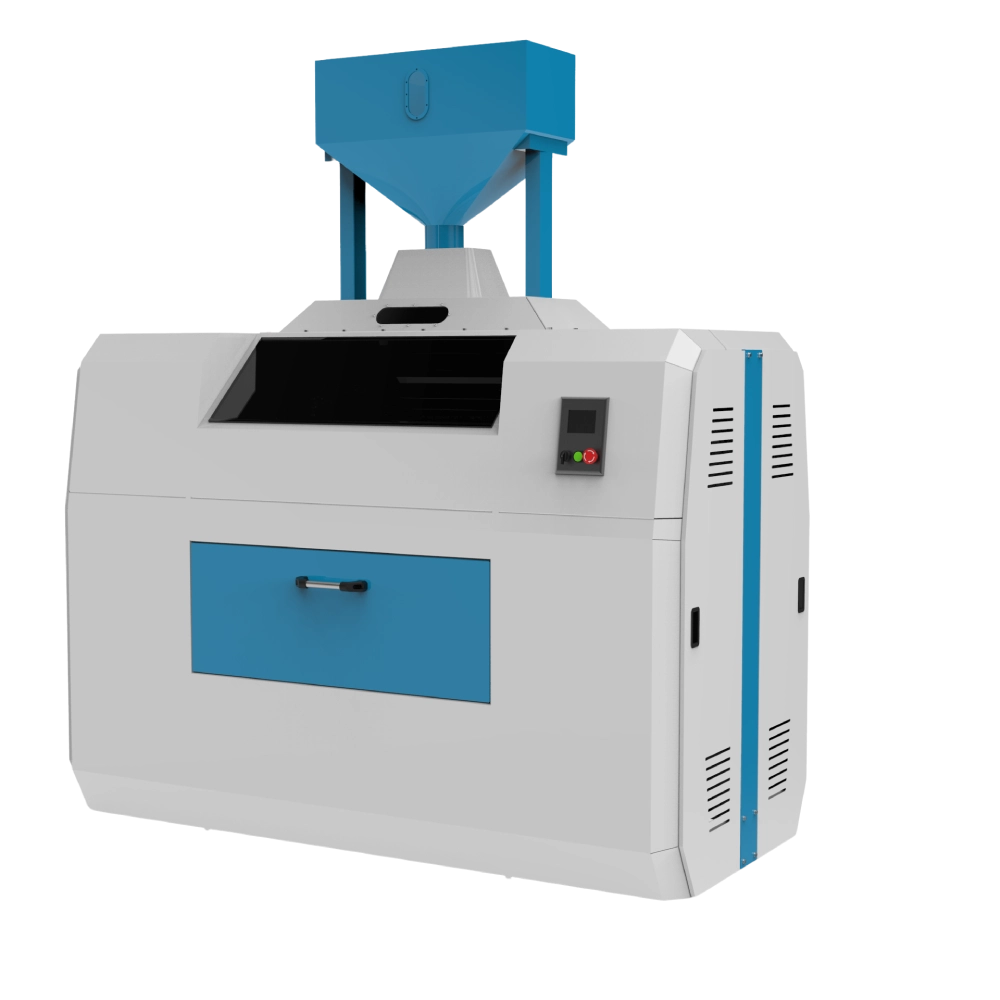

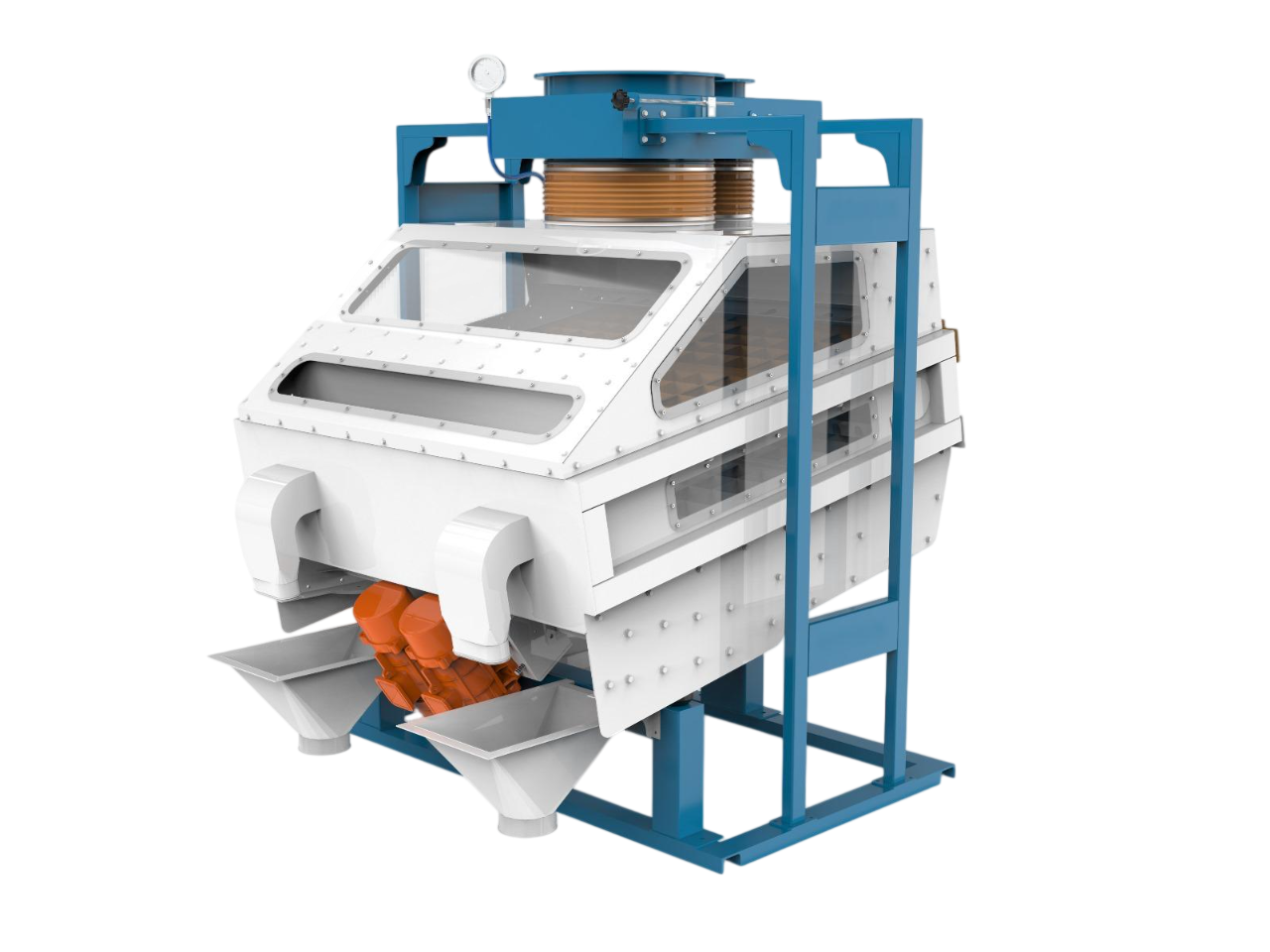

Cleaning Unit

Cleaning units improve raw material quality by effectively separating foreign substances before production. They contribute to the efficient and safe operation of the production line.

Effective Foreign Substance Separation

It ensures clean production by precisely separating dust, stones, and unwanted particles.

Seamless Line Compatibility

Its high-capacity structure allows it to integrate seamlessly into the production line.

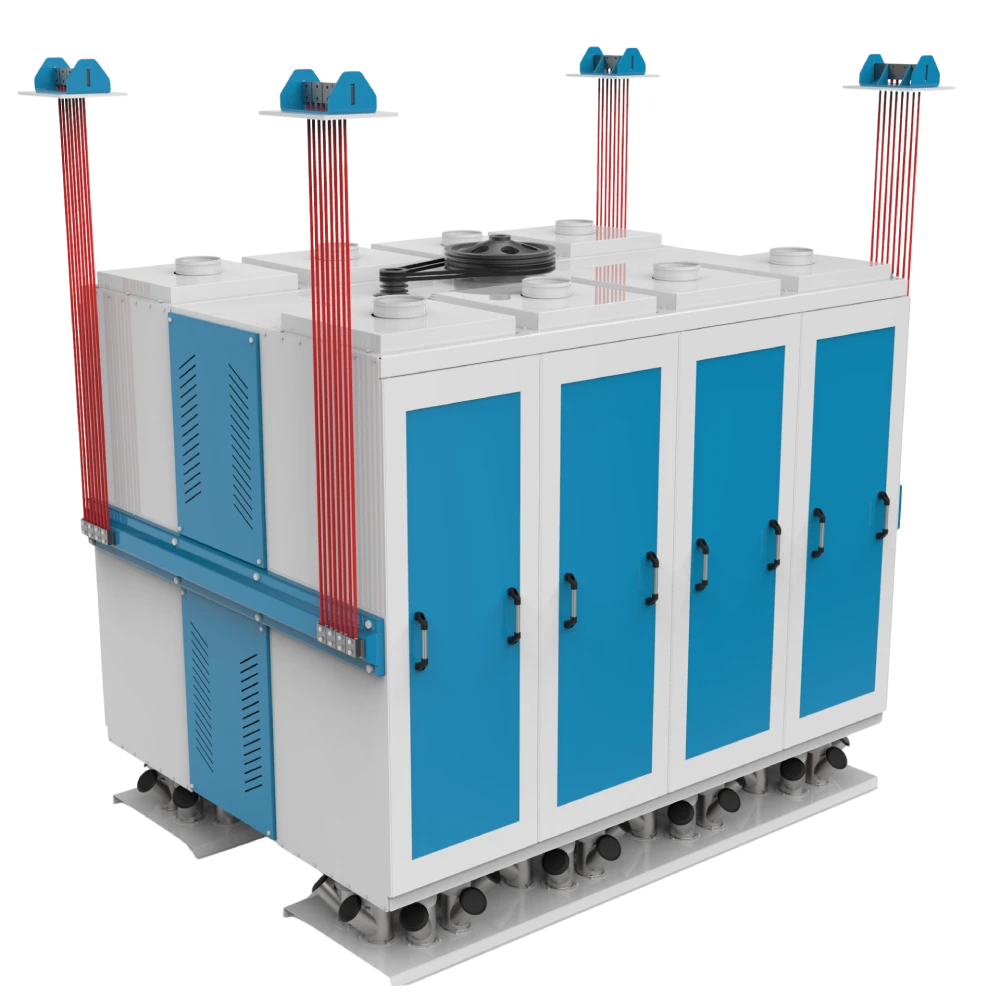

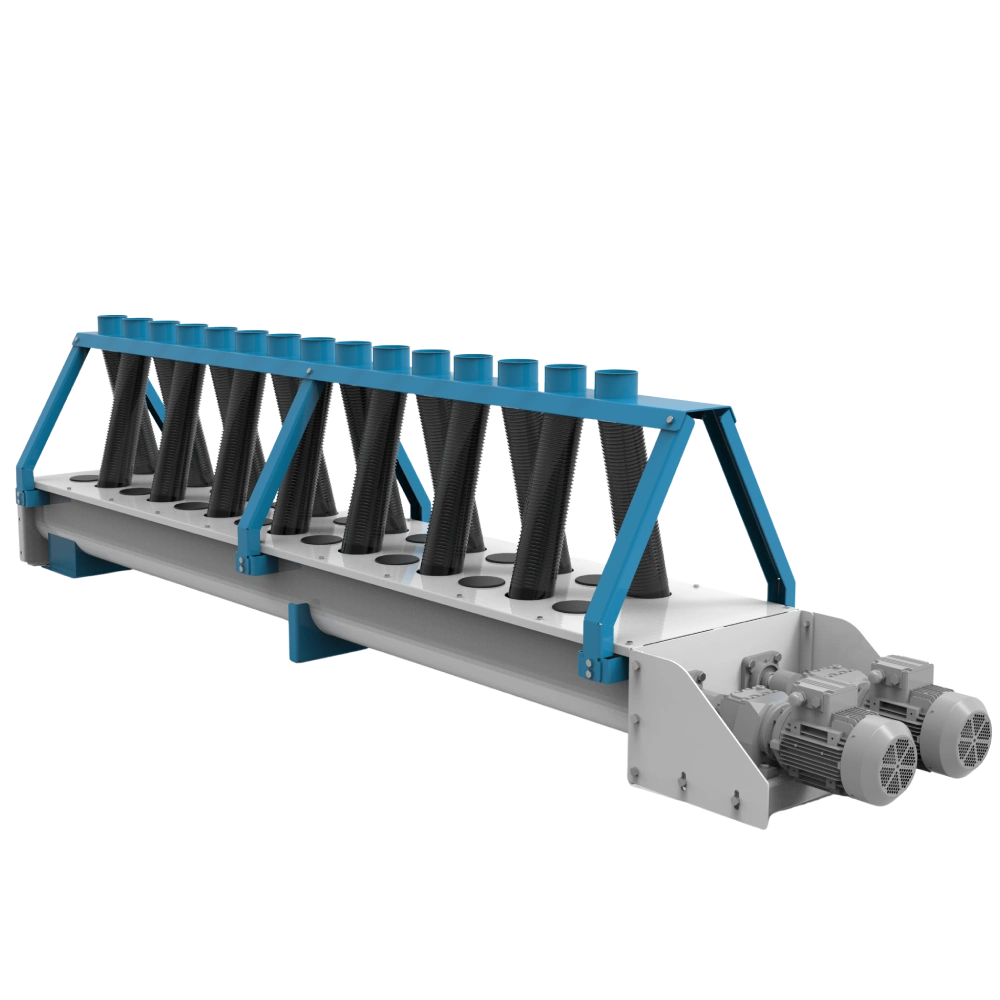

Conveying Unit

Yılmazoğulları Conveying Units ensure the safe and orderly transfer of raw materials and products along the production line. Efficient flow supports production continuity.

Safe Material Transfer

It offers a controlled and balanced transportation method without damaging the product.

High Capacity, Low Loss

Its optimized design increases flow efficiency and reduces waste.

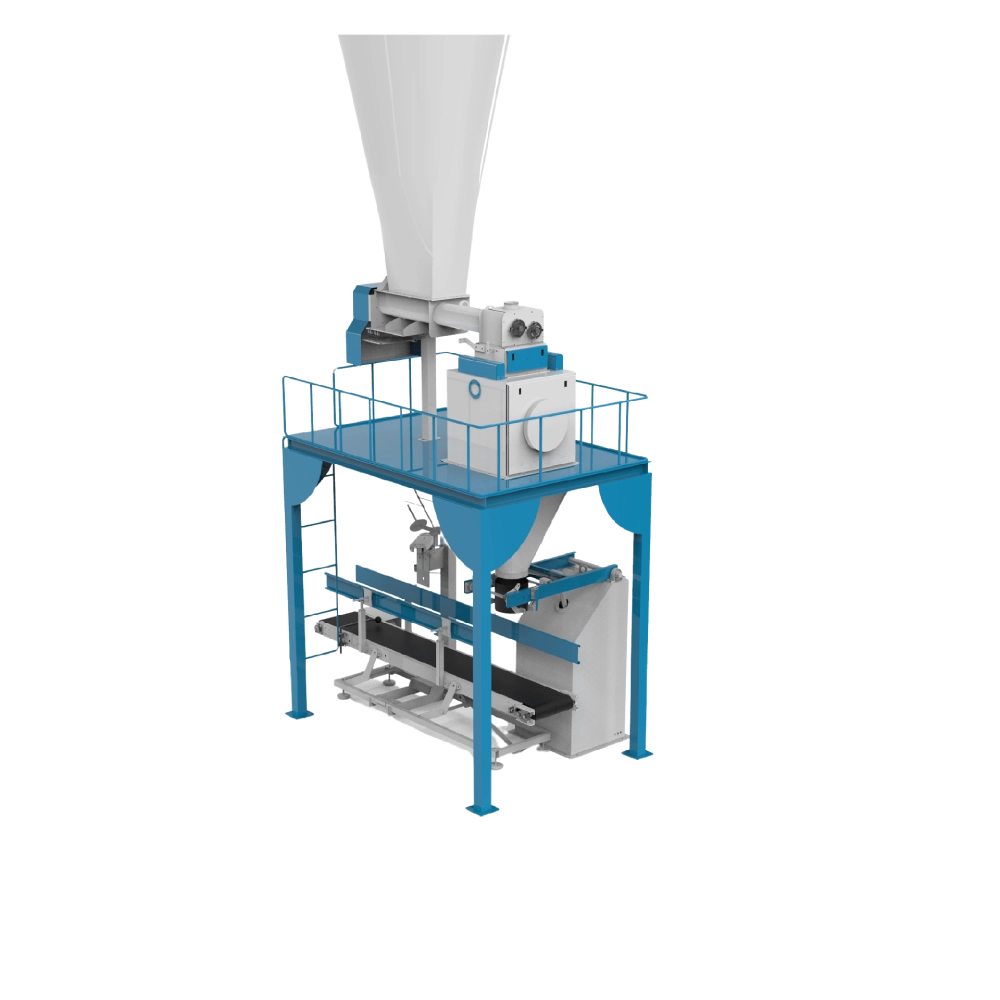

Packaging Unit

Packaging units ensure that products are packaged quickly, neatly, and according to standards. They increase both operational speed and product safety.

Precise and Meticulous Packaging

It delivers professional results while maintaining product weight and packaging quality.

Industrial Speed and Reliability

Its design, suitable for high-volume production, saves time and labor.

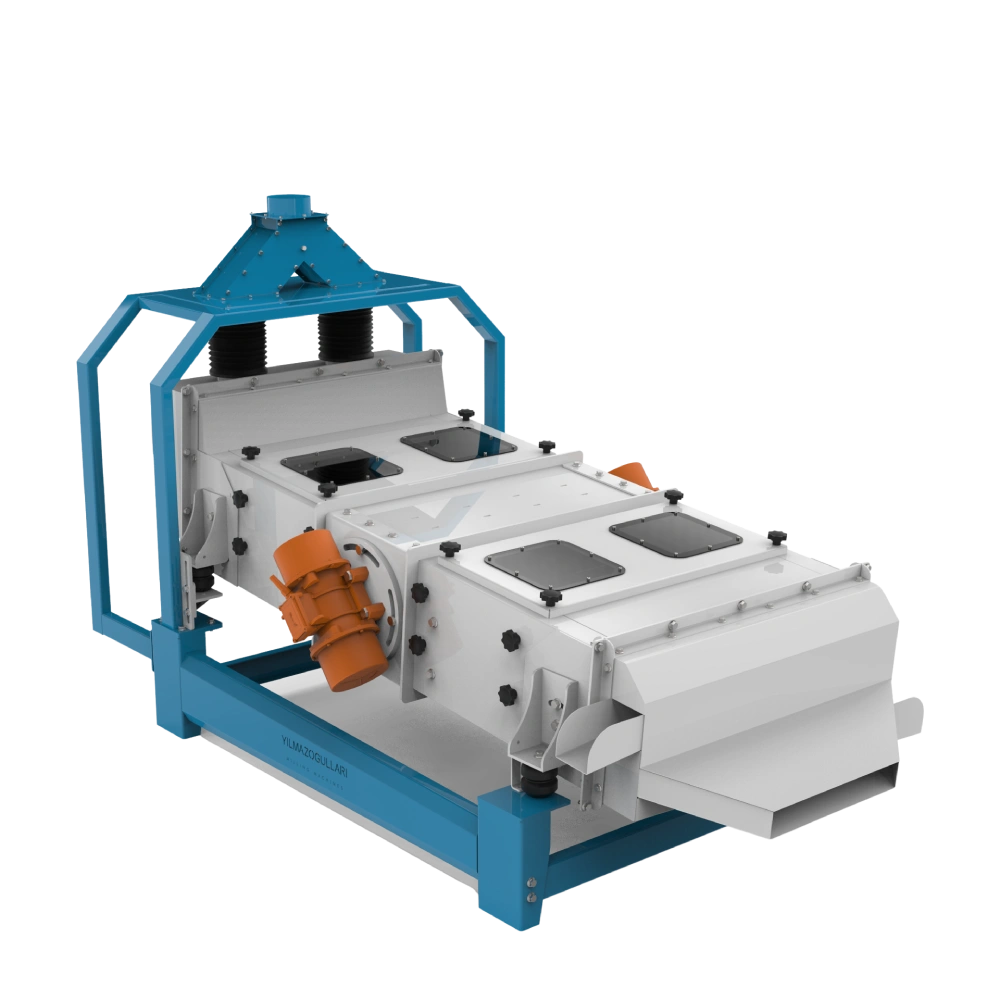

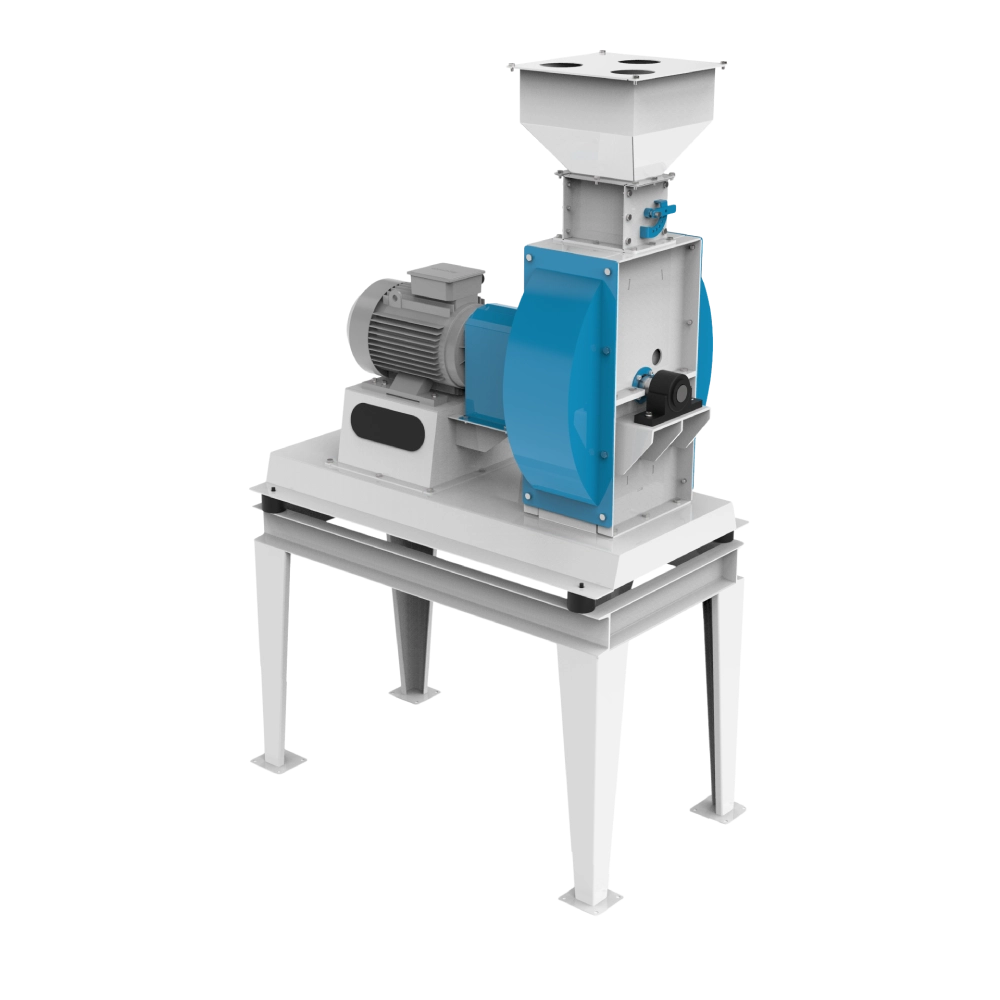

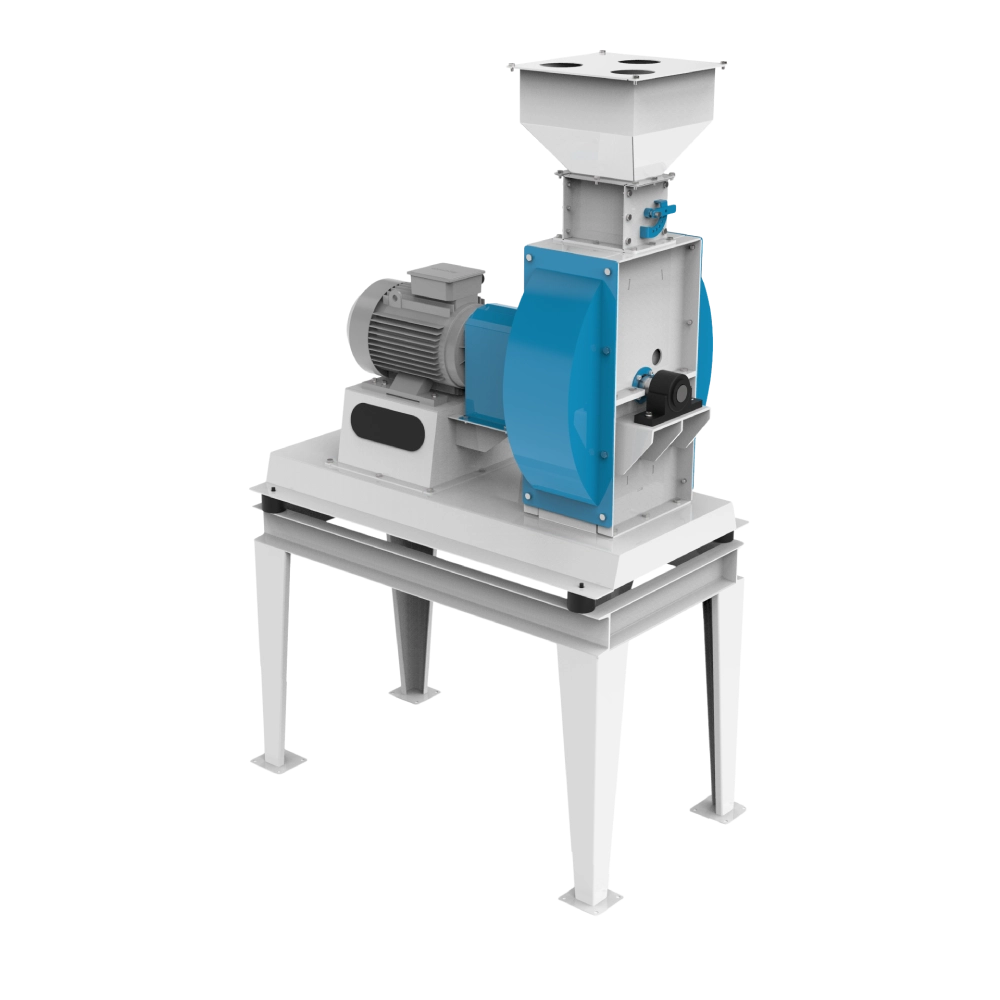

Bulgur Feed Crushing Units

Specifically developed for bulgur and feed crushing processes, these units allow for precise achievement of the desired grain structure. Their robust construction makes them suitable for continuous production.

Controlled Grain Size

A standard and consistent product is obtained through an adjustable crushing system tailored to the specific needs.

Designed for Harsh Conditions

It delivers high performance even with prolonged and intensive use.

YILMAZOĞULLARI PRODUCTS

AİR JET FILTER

unit

Aspirator Unit

Hammer Mill

AİR JET FILTER

unit

Aspirator Unit

Hammer Mill

Why Choose Yılmazoğulları?

We Are the #1 Milling Machinery Manufacturer

With over 30 years of experience, export strength reaching more than 50 countries, and a quality-driven production philosophy, we rank among the leading brands in the industry. By prioritizing customer satisfaction and reliable service, we deliver sustainable quality in every project. The strong working environment we provide for our team, the value we place on our business partners, and the solid relationships we build with our suppliers make us a preferred manufacturer worldwide.

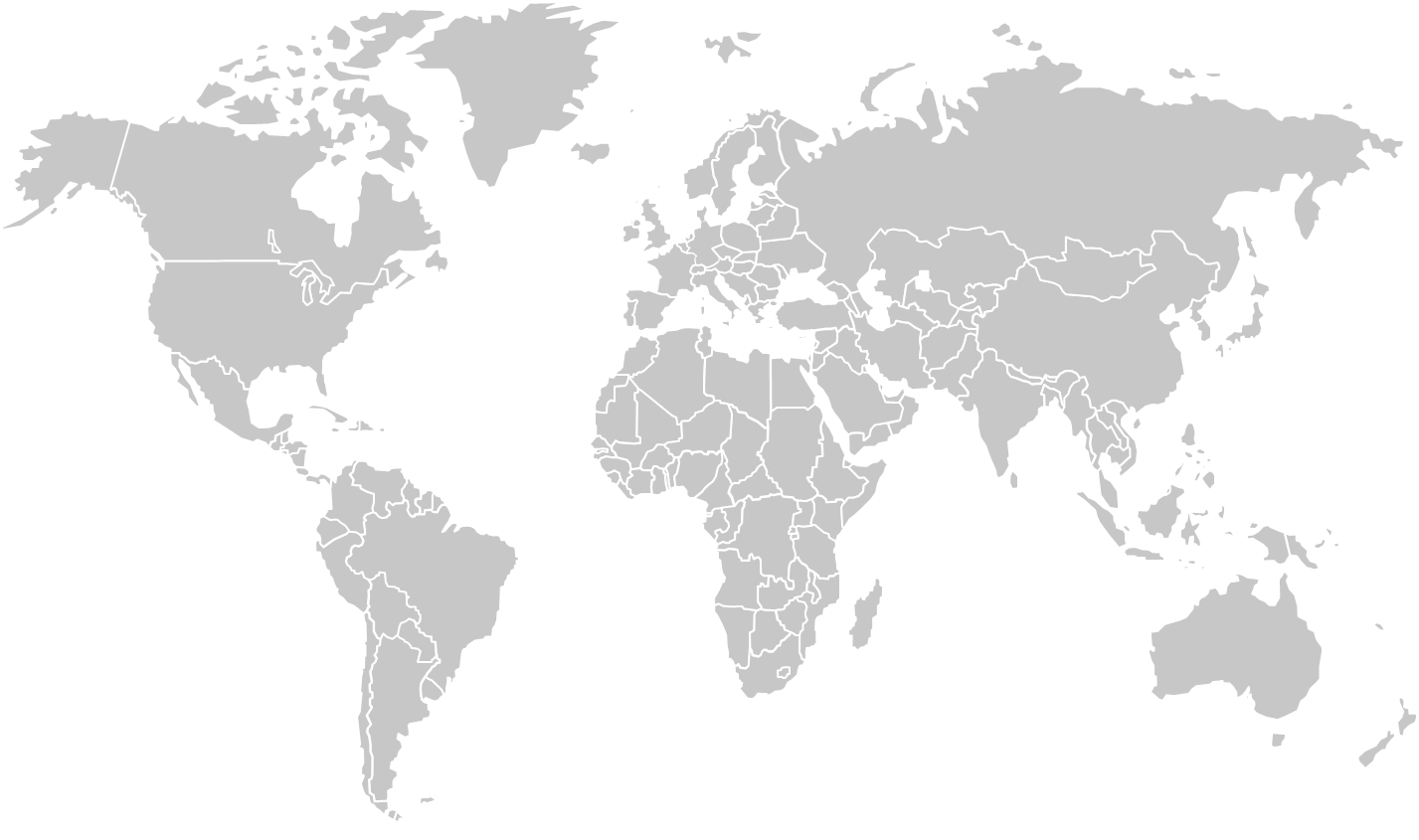

Countries Where Our Milling Machines

Operate

France

Germany

Poland

Ukraine

Russia

South Korea

Japan

Argentina

Brazil

Mexican

United States

Canada

Iceland

United Kingdom

Norway

Sweden

Nigeria

Egypt

Algeria

Morocco

Colombia

Peru

Chile

Bolivia

Venezuelan

Tunisian

Sudan

Somali

Kenya

Tanzania

South Africa

Saudi Arabia

United Arab Emirates

Qatar

Jordanien

Yemen

Iraq

Iranian

Afghanistan