CONTACT US

- +90 332 251 18 04

- +90 332 251 18 04

- bilgi@yilmazogullaridegirmen.com.tr

- Büyük Kayacık Mah. 3. Organize Sanayi Bölgesi 7 Nolu Sokak No:25 Selçuklu / Konya / Türkiye

Product Categories

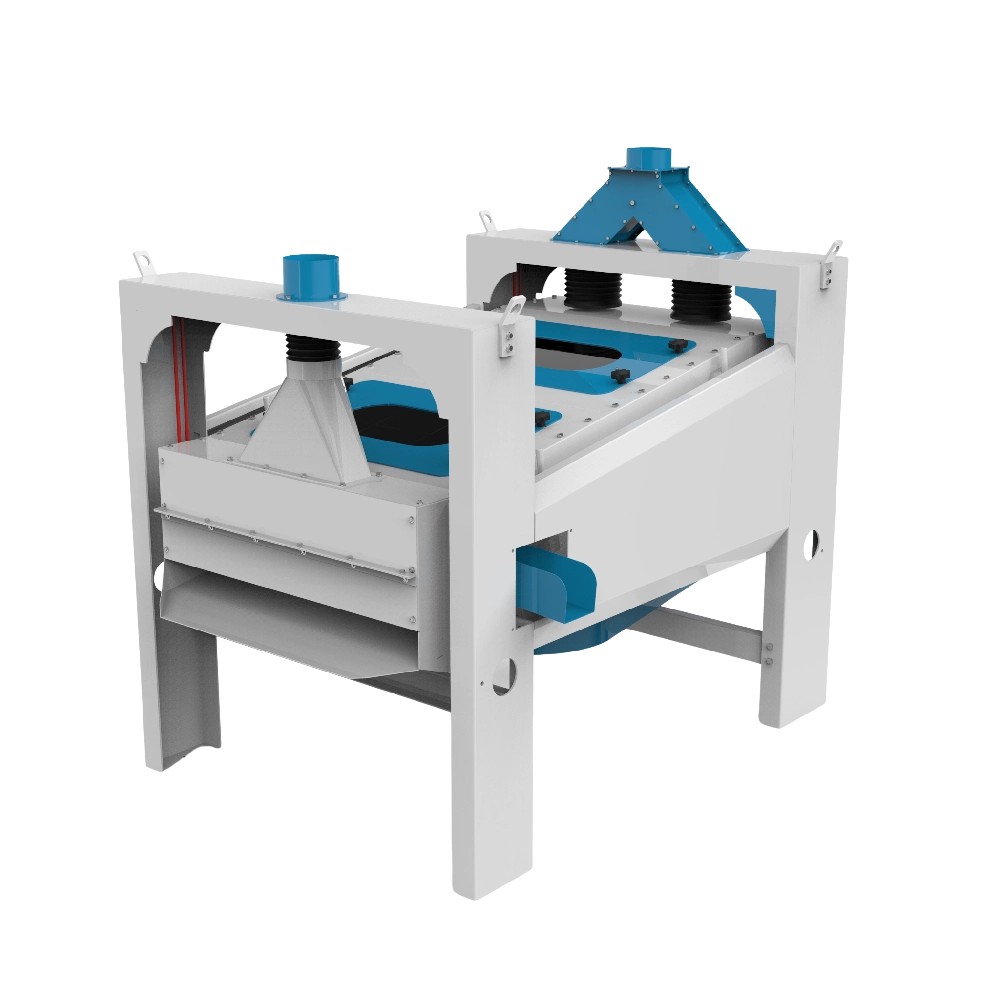

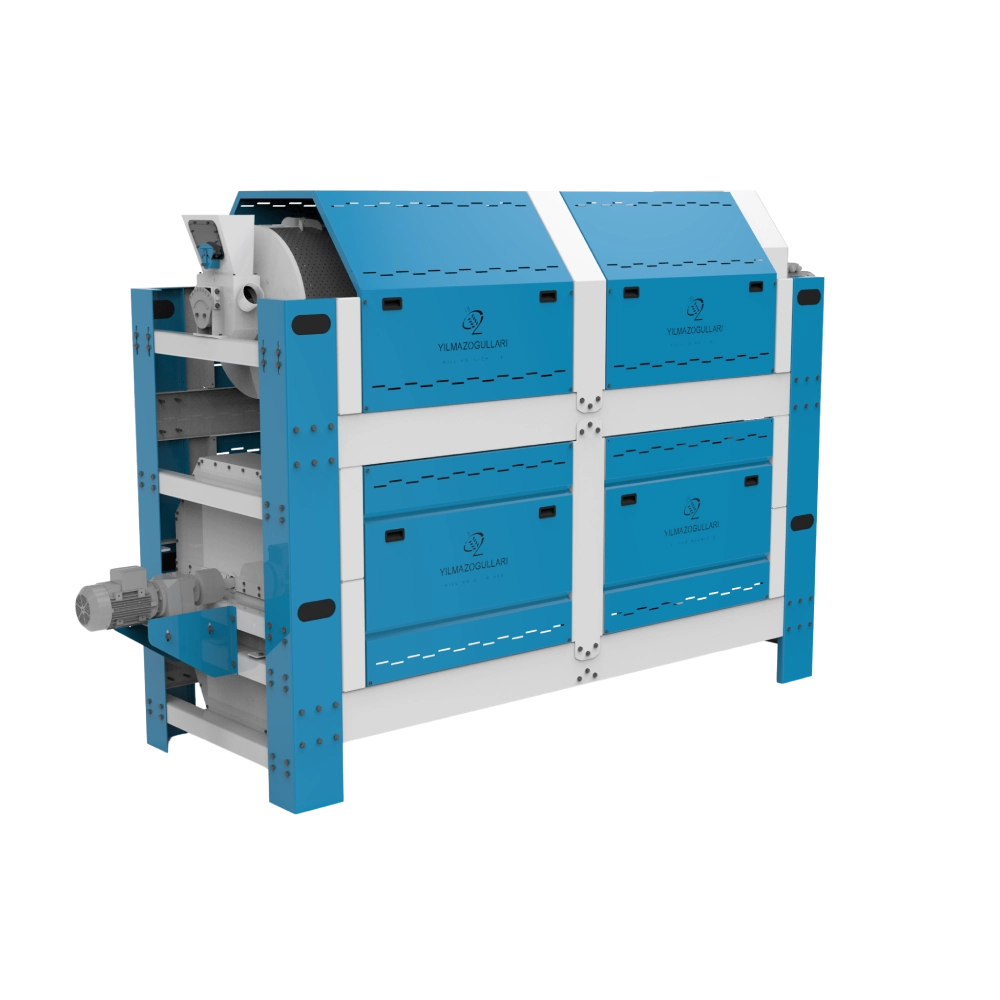

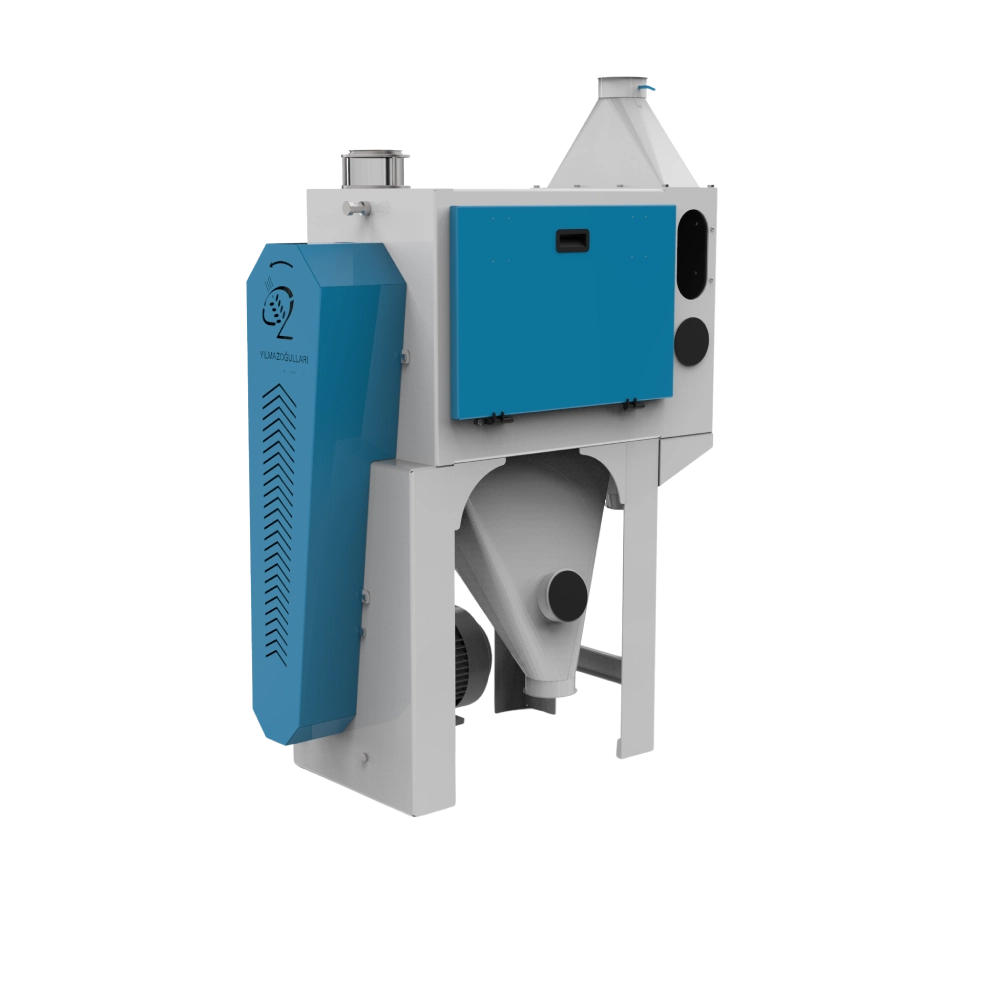

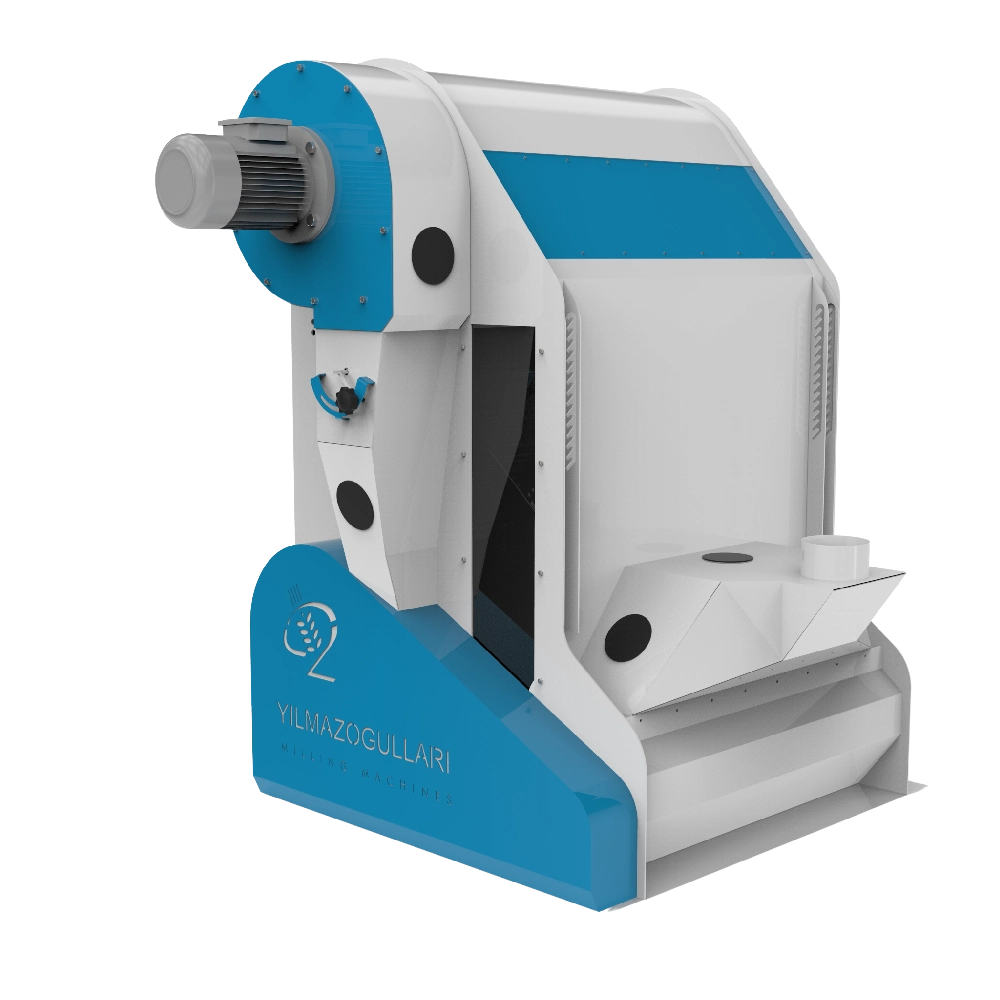

The Role of the Cleaning and Conditioning Unit in the Production Process

The cleaning and conditioning unit is a preliminary processing stage that optimizes the physical purity and moisture balance of raw materials before they enter the production line. This unit represents a critical starting point to ensure a healthy and efficient production flow.

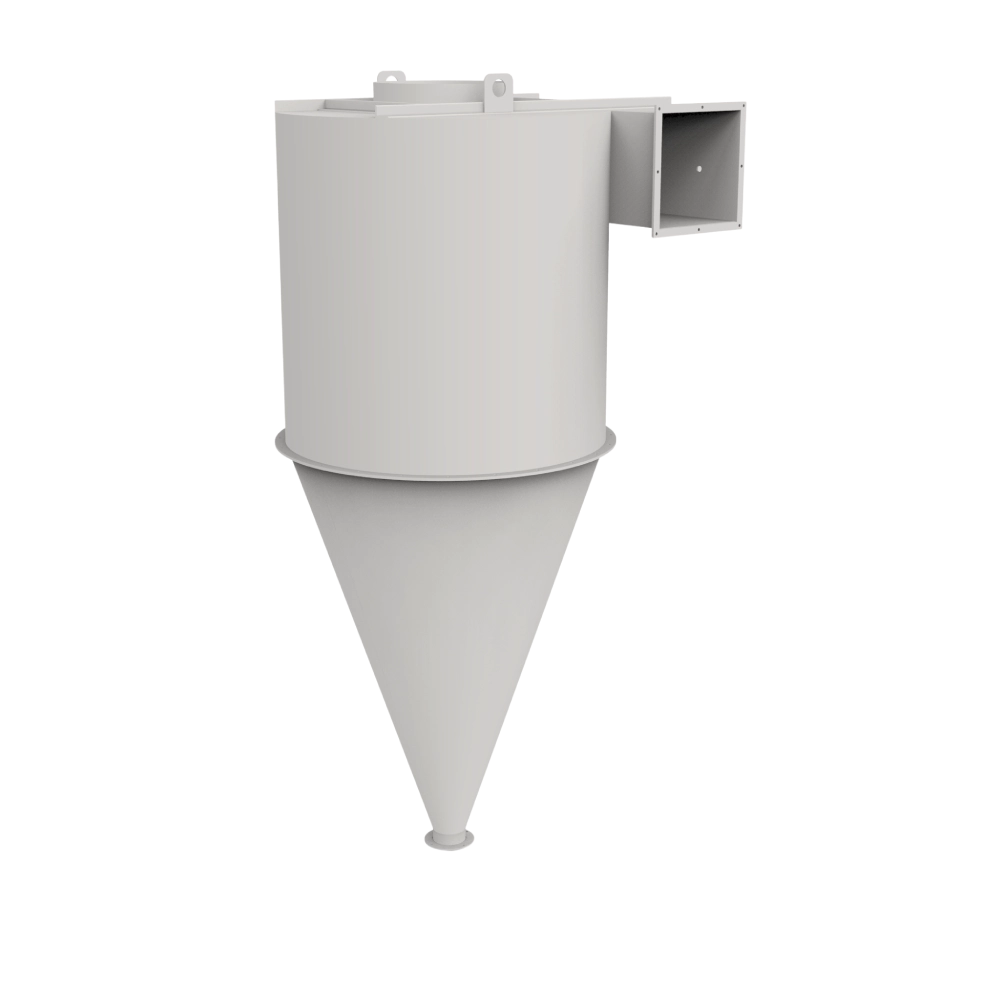

During the cleaning stage, dust, stones, foreign materials, and light impurities are removed from the product. In the conditioning process, the moisture content of the material is carefully adjusted to prepare its internal structure for grinding and crushing operations. The combined and synchronized operation of these two stages prevents quality losses in subsequent processing steps.

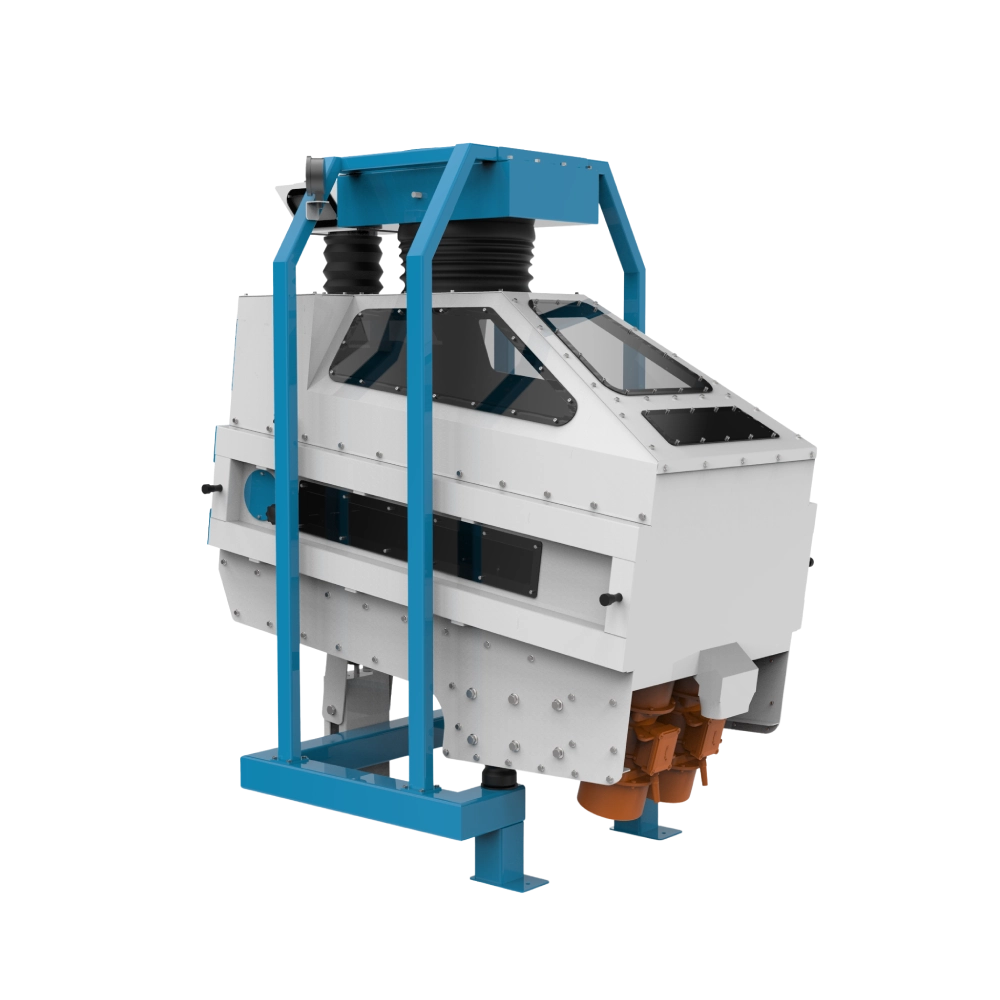

Benefits of the Cleaning and Conditioning Unit

The cleaning and conditioning unit plays a key role in maintaining product quality throughout production. Raw materials that are free from impurities and properly moisture-balanced allow grinding and crushing units to operate in a more stable and controlled manner.

Proper conditioning reduces product breakage and helps preserve the grain structure. It also minimizes machine wear, extending equipment lifespan. Cleaning and conditioning units are essential systems that ensure continuity, quality, and operational reliability within the production line.