CONTACT US

- +90 332 251 18 04

- +90 332 251 18 04

- bilgi@yilmazogullaridegirmen.com.tr

- Büyük Kayacık Mah. 3. Organize Sanayi Bölgesi 7 Nolu Sokak No:25 Selçuklu / Konya / Türkiye

Product Categories

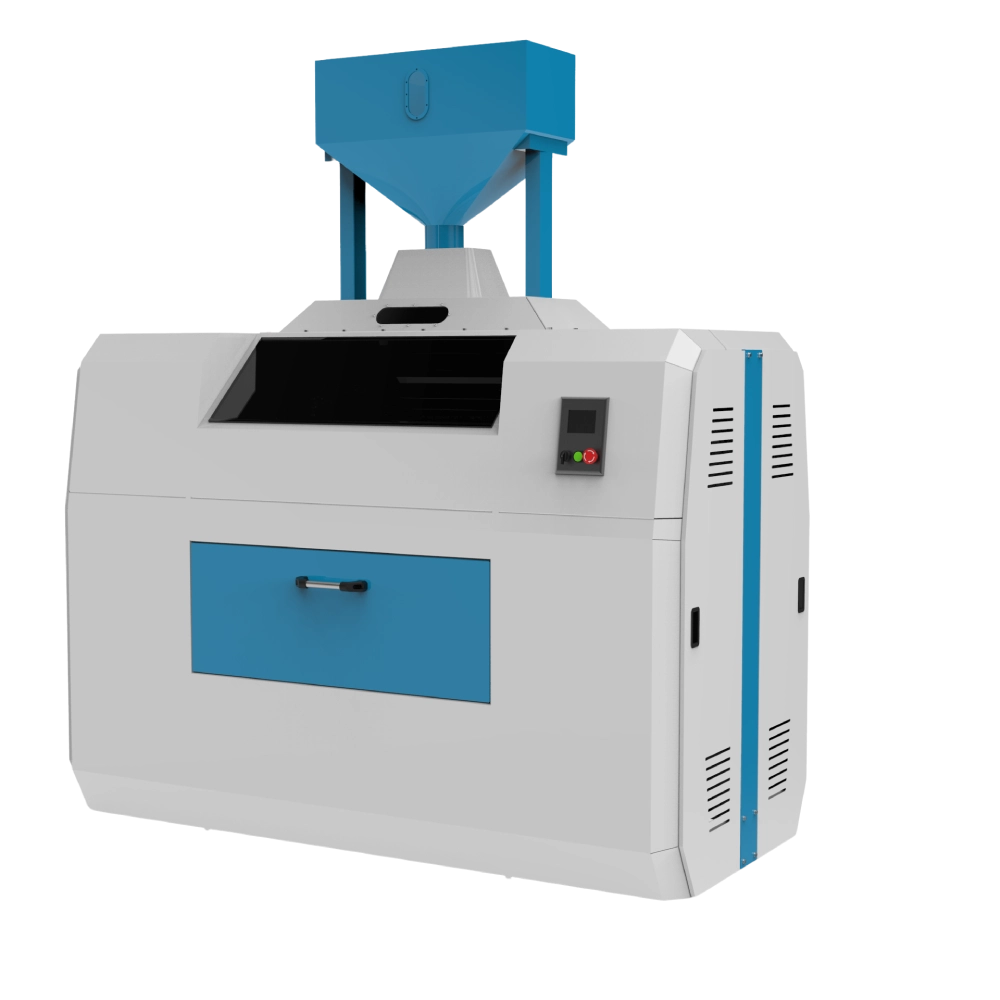

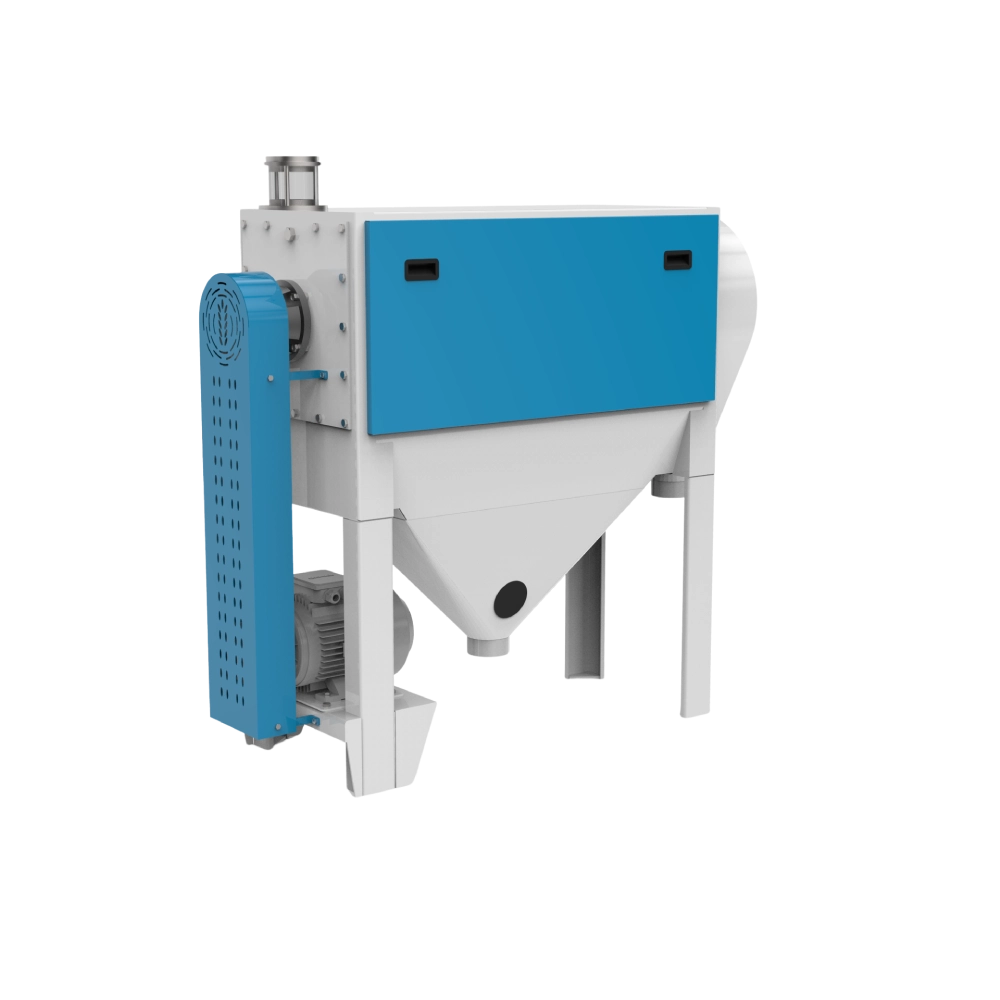

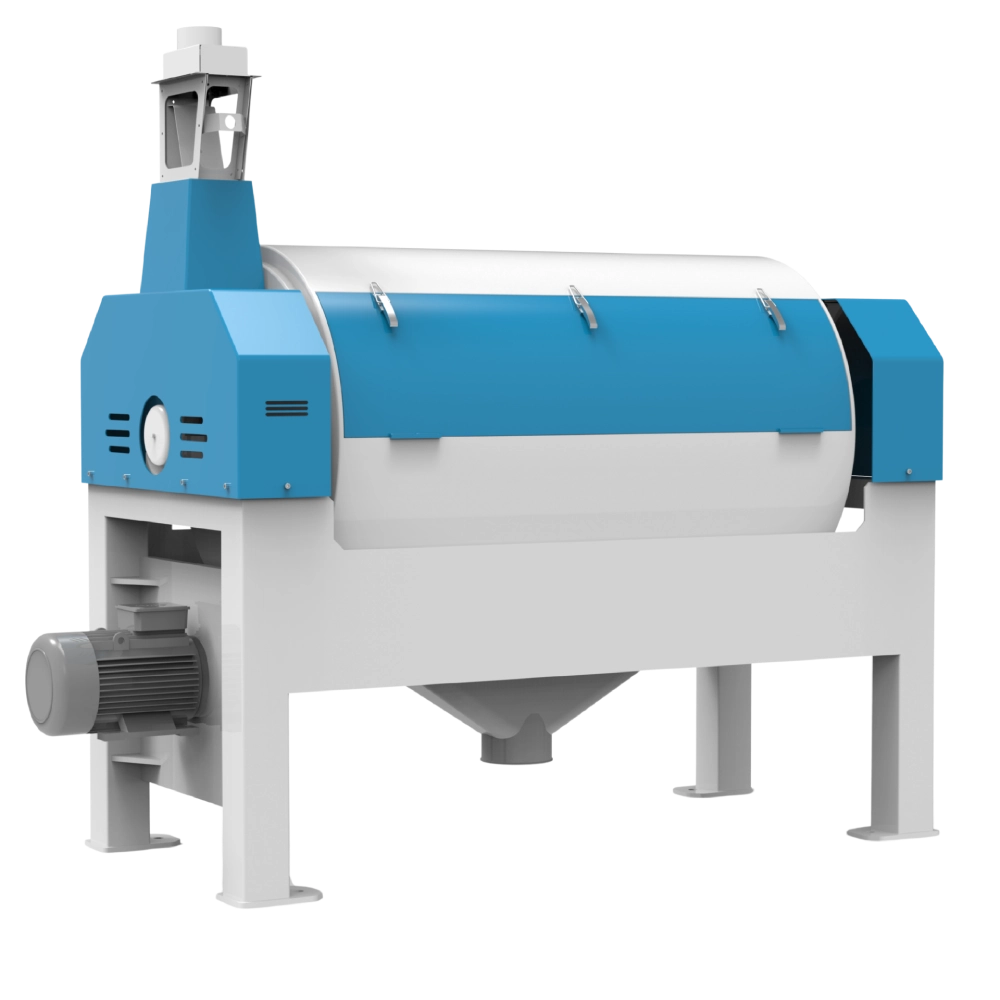

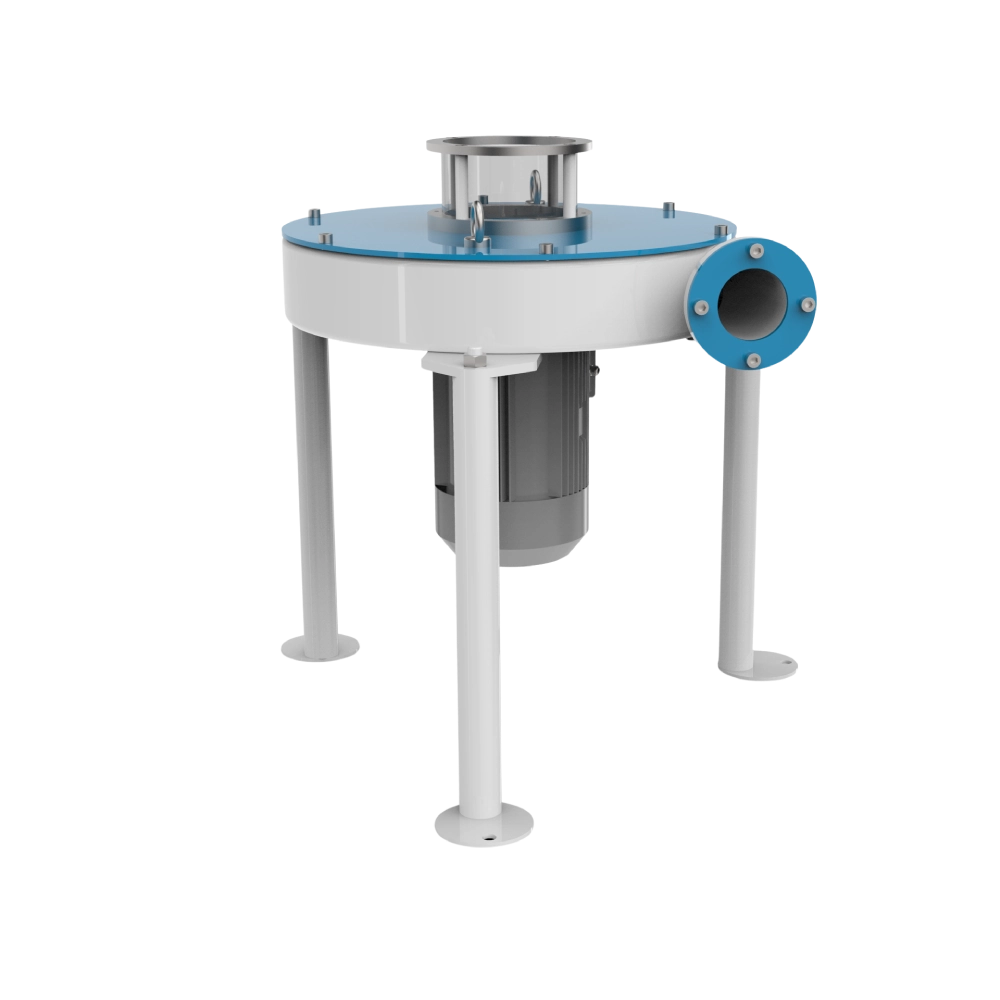

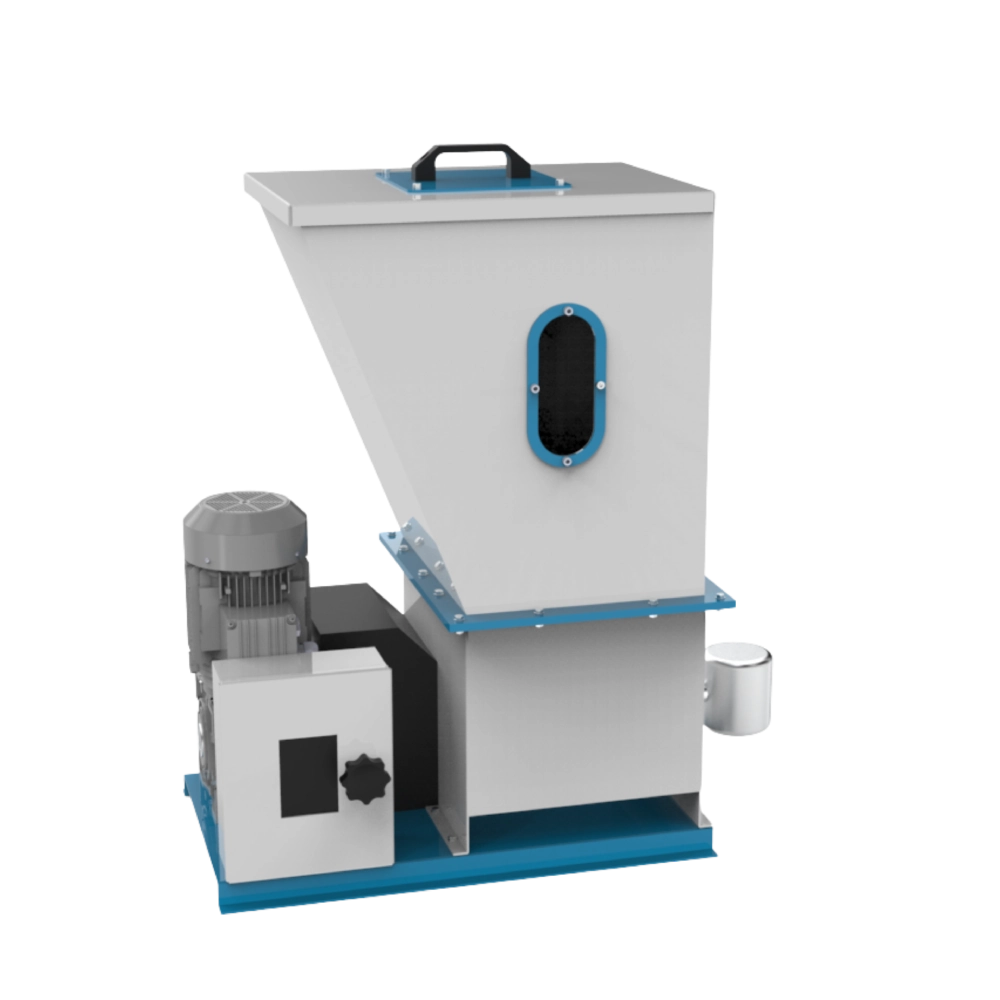

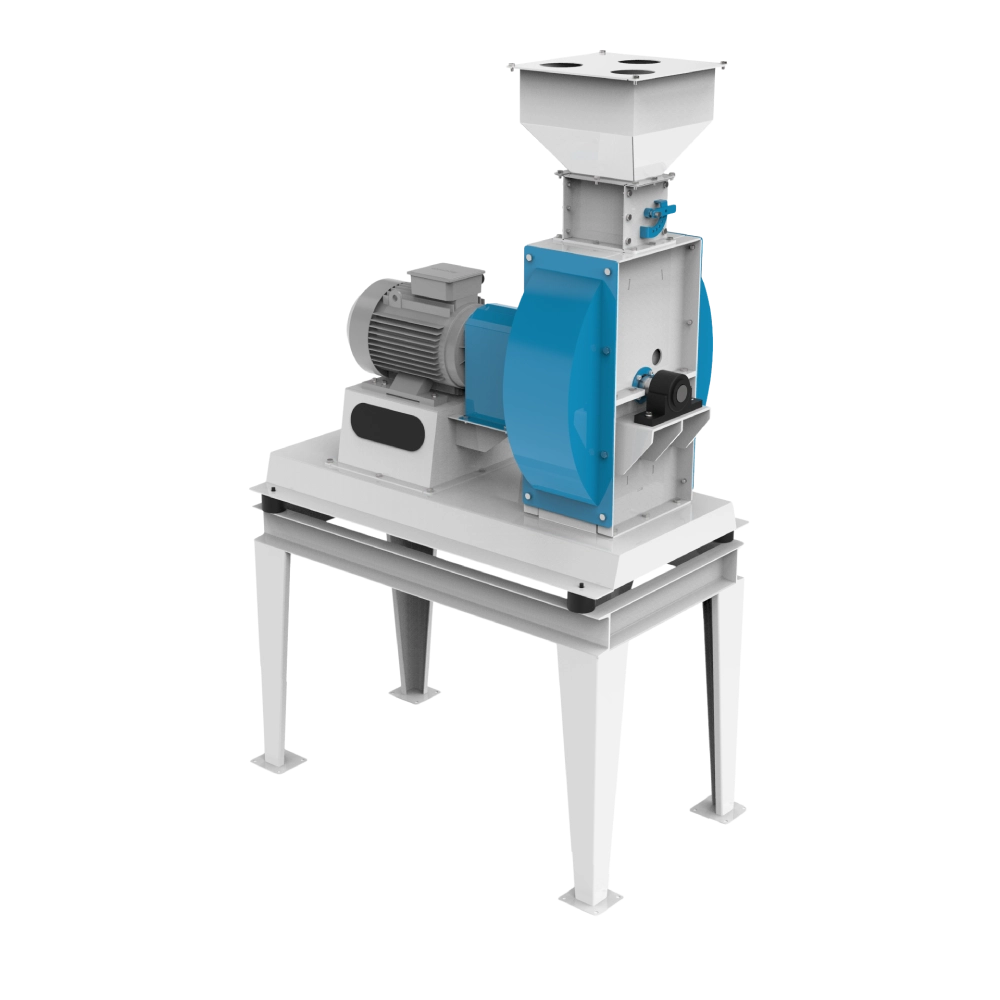

Function of the Grinding Unit and Its Position in the System

The grinding unit is one of the core process components that reduces raw materials to the required particle size and directly affects product quality within the production line. In the processing of grains, feed, and similar products, it enables the material to achieve a balanced and suitable structure for subsequent stages.

These units process raw materials without damaging their structure through controlled feeding and adjustable grinding mechanisms. Maintaining a stable material flow ensures continuity in the production line in terms of both capacity and quality. The grinding unit is positioned at a critical point that determines the overall efficiency of the system.

Advantages of the Grinding Unit in Production

Grinding units ensure homogeneity and repeatable quality in production. Balanced grinding standardizes particle size, positively impacting packaging and storage processes while also reducing product loss.

With their durable mechanical structure and design suitable for long-term operation, grinding units deliver reliable performance under intensive production conditions. Ease of adjustment and maintenance minimizes downtime, providing operational advantages for facilities.

A properly selected and correctly positioned grinding unit ensures balanced, controlled, and sustainable operation of the production line.