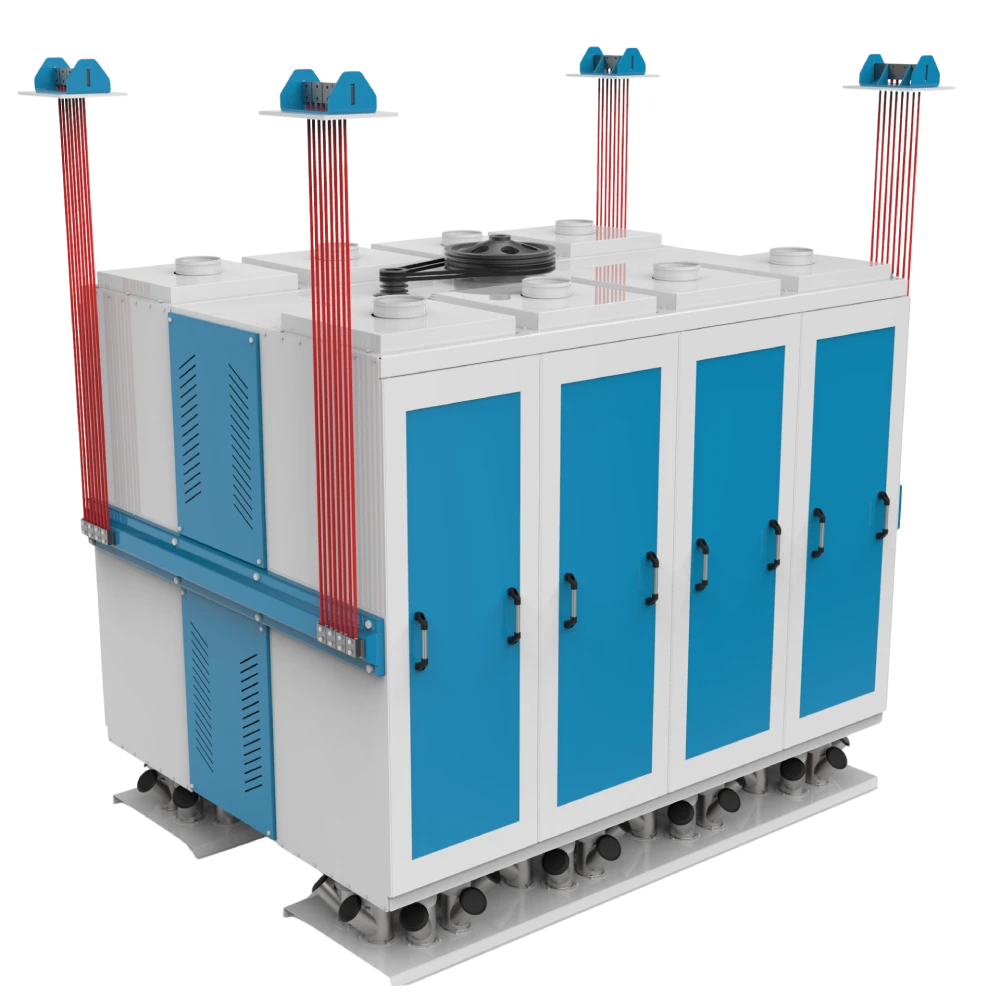

SQUARE TYPE PLANSIFTER is a high-performance screening machine developed for precise sieving, classification, and separation of intermediate products in the milling lines of flour and semolina mills. After coarse and high grinding stages, mixtures of semolina, flour, and bran are accurately separated into the desired particle sizes through this system. The machine features steel-constructed cabinets housing sieve frames with different calibrations, allowing each product to be processed according to its specific quality standards. Its centrally oscillating body structure, supported by a specially designed weight group mounted from the top and bottom around the center of gravity, ensures uniform vibration distribution across the entire surface and smooth, controlled product flow over the sieve frames. This design enables clean, efficient, and highly controlled classification of milled material. The robust chassis withstands intensive operating conditions, while maintenance and cleaning are designed to be quick and practical. By allowing different sieve frames to be used in different passages, the Square Type Plansifter offers flexible solutions for modern production lines. For producers aiming to improve product quality, reduce losses, and achieve greater process control in flour and semolina production, the Square Type Plansifter delivers professional and reliable screening performance.

CONTACT US

- +90 332 251 18 04

- +90 332 251 18 04

- bilgi@yilmazogullaridegirmen.com.tr

- Büyük Kayacık Mah. 3. Organize Sanayi Bölgesi 7 Nolu Sokak No:25 Selçuklu / Konya / Türkiye

- Home

- SQUARE TYPE PLANSIFTER

SQUARE TYPE PLANSIFTER

YILMAZ OĞULLARI

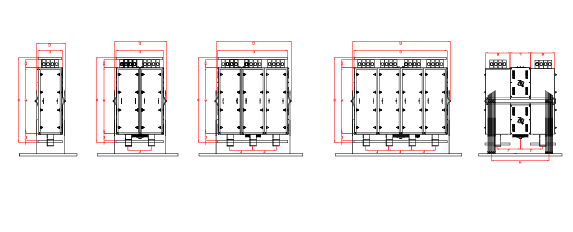

Technical Table

Technical Table

| MODEL TİPİ | Teknik Özellikler | Ölçüler (mm) | Ağırlık (kg) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pasaj Sayısı | Kasa Sayısı | Eleme Alanı (m²) | Motor Gücü (kW) | A | B | C | D | E | F | G | H | J | K | ||||

| N | S | ||||||||||||||||

| YMS KRE 2/20 | 2 | 17-20 | 8,5-10 | 10-12 | 2.2 | 1720 | 2400 | 750 | 400 | 280 | 750 | 900 | 1550 | 750 | 750 | 1450 | |

| YMS KRE 2/24 | 2 | 20-24 | 10-12 | 12-14 | 2.2 | 1850 | 2530 | 750 | 400 | 280 | 750 | 900 | 1550 | 750 | 750 | 1600 | |

| YMS KRE 2/28 | 2 | 24-28 | 12-14 | 14-16 | 3 | 2150 | 2830 | 750 | 400 | 280 | 750 | 900 | 1550 | 750 | 750 | 1780 | |

| YMS KRE 4/20 | 4 | 17-20 | 17-20 | 20-24 | 3 | 1720 | 2400 | 1500 | 400 | 280 | 750 | 1650 | 1550 | 750 | 750 | 2550 | |

| YMS KRE 4/24 | 4 | 20-24 | 20-24 | 24-28 | 4 | 1850 | 2530 | 1500 | 400 | 280 | 750 | 1650 | 1550 | 750 | 750 | 2600 | |

| YMS KRE 4/28 | 4 | 24-28 | 24-28 | 28-33 | 4 | 2150 | 2830 | 1500 | 400 | 280 | 750 | 1650 | 1550 | 750 | 750 | 2850 | |

| YMS KRE 6/20 | 6 | 17-20 | 25-30 | 30-36 | 4 | 1720 | 2400 | 2250 | 400 | 280 | 750 | 2400 | 1550 | 750 | 750 | 2950 | |

| YMS KRE 6/24 | 6 | 20-24 | 30-36 | 36-43 | 4 | 1850 | 2530 | 2250 | 400 | 280 | 750 | 2400 | 1550 | 750 | 750 | 3350 | |

| YMS KRE 6/28 | 6 | 24-28 | 36-42 | 43-50 | 4 | 2150 | 2830 | 2250 | 400 | 280 | 750 | 2400 | 1550 | 750 | 750 | 3800 | |

| YMS KRE 8/20 | 8 | 17-20 | 34-40 | 40-48 | 4 | 1720 | 2400 | 3000 | 400 | 280 | 750 | 3150 | 1550 | 750 | 750 | 3600 | |

| YMS KRE 8/24 | 8 | 20-24 | 40-48 | 48-57 | 5.5 | 1850 | 2530 | 3000 | 400 | 280 | 750 | 3150 | 1550 | 750 | 750 | 4100 | |

| YMS KRE 8/28 | 8 | 24-28 | 48-56 | 57-67 | 7.5 | 2150 | 2830 | 3000 | 400 | 280 | 750 | 3150 | 1550 | 750 | 750 | 4800 | |

SQUARE TYPE PLANSIFTER

HIGH QUALITY

SQUARE TYPE PLANSIFTER

Frequently Asked Questions

Which raw materials can Yılmazoğulları milling machines be used for processing?

At Yılmazoğulları, we manufacture milling machines that can be used in a wide range of applications, from flour production to feed factories, from spice grinding to the crushing of mineral-based products. Our systems enable the efficient processing of grains such as wheat, barley, and corn, as well as various granular and micronized products such as lentils, chickpeas, black pepper, rock salt, and calcite.

How is energy efficiency achieved in Yılmazoğulları machines?

Energy efficiency is one of the fundamental criteria that Yılmazoğulları prioritizes in its design and engineering process. Thanks to our specialized motor technologies, intelligent frequency control systems, and optimized rotor-switching designs, we achieve low energy consumption without compromising production capacity. This allows you to minimize your operating costs while also supporting environmental sustainability.

What kind of support does Yılmazoğulları provide during the machine installation and commissioning process?

Yılmazoğulları never leaves its customers alone during the after-sales technical support processes. All our machines are installed on-site by our expert engineers and commissioned with operator training. In addition, your operational continuity is ensured with spare parts supply, maintenance protocols, and remote support services.

Contact US

- +90 332 251 18 04

- +90 332 251 18 04

- bilgi@yilmazogullaridegirmen.com.tr

- Büyük Kayacık Mah. 3. Organize Sanayi Bölgesi 7 Nolu Sokak No:25 Selçuklu / Konya / Türkiye